Collet Instruments was founded on June 6, 2025 (Instrument Day) in Hamamatsu, the "City of Music" where world-leading instrument manufacturers gather.

After engaging in the design and development of electronic musical instruments at a major instrument manufacturer, Shohei Kubo established Collet Instruments in 2025. The core of his business's product development utilizes "MIDI 2.0," a technology announced in 2019. MIDI 2.0 is an extended standard of the common protocol "MIDI" (Musical Instrument Digital Interface, often called MIDI 1.0 to distinguish it from MIDI 2.0), which was born in the early 1980s to transmit digitized performance information between devices like electronic instruments and computers—in other words, it is the "evolved MIDI."

MIDI is a technology indispensable for today's music production using PCs and electronic instruments. Collet Instruments is applying the further-enhanced MIDI 2.0 to develop converters and new electronic instruments. We asked Mr. Kubo in detail about the potential of MIDI 2.0 and the origins of his manufacturing philosophy.

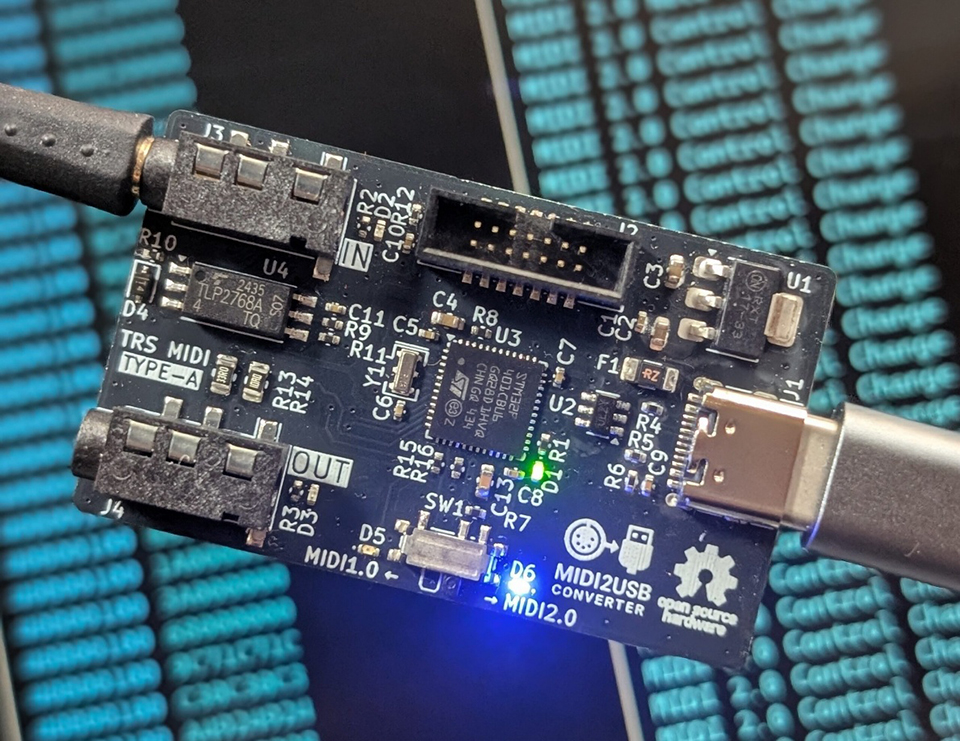

MIDI2USB CONVERTER Development Board

MIDI2USB CONVERTER Development BoardBefore entering the path of instrument making, you studied mechanical engineering at the Osaka Prefecture College of Technology. What led you to transition into the field of music?

Kubo: I've always loved music, so I started a band and played the bass after entering the technical college. However, band activities were strictly a hobby; what I focused on during my time there was building robots for the "Robocon" competition. I was part of a team of about 30 people who collaborated to build a single robot, and we even won the Kinki regional tournament of the "NHK College of Technology Robocon" competition.

Winning Robocon! What kind of robots did you build?

Kubo: I built various robots, but the one I remember most vividly was modeled after my hometown, Osaka: a robot where two middle-aged women holding shopping bags engaged in a *chanbara* (sword fighting) duel to grab products (laughs).

That sounds like a very interesting robot (laughs).

Kubo: In the College of Technology Robocon, besides the championship, there's also the "Robocon Grand Prize," awarded to robots that stand out for their original ideas and overall technical prowess. While building a strong robot to win the competition is, of course, important, the event also values the ability to create robots that only your team can make. The robot based on the middle-aged women was one I made in my final year of Robocon participation. I heavily prioritized "how unique a robot we could make" over winning the competition. Although this robot wasn't strong enough to score many points, it did catch the attention of a TV program. That's when I realized the importance of not just building technically excellent, strong robots, but also effectively communicating the charm of "manufacturing that only we can do."

The "unique and free manufacturing" you experienced in Robocon seems to be reflected in the self-made instruments of "Neya Gakki" (Neya Instruments), an activity you've continued for over 10 years.

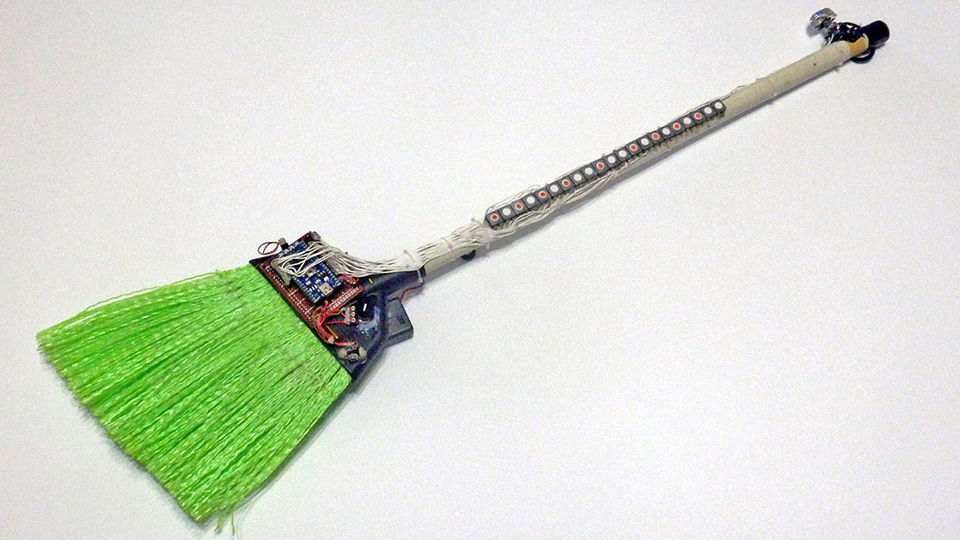

Kubo: That's right. After gaining the ability to create various things myself while at the technical college, I started thinking about making things other than robots. Since I was in a band and loved music at the time, I began making musical instruments myself. Initially, I made practical items like effect pedals, but gradually I started wanting to create something completely original and unique, not just things sold in stores. The first original creation I made was the "Broom Guitar." It's shaped like a broom, but just like a real electric guitar, it has buttons corresponding to the frets. When you strum or tap the brush part, a sensor reacts and produces sound.

The broom air guitar, which we often saw during school cleaning time, realized as an actual instrument!

Kubo: I showcased this Broom Guitar at the school's cultural festival, and many people found it interesting. Similar to Robocon, I realized that creating and presenting unique things was what I wanted to do, so I started "Neya Gakki (※1)" as a hobby to make my own interesting instruments.

※1: "Neya Gakki" was named by combining "Neyagawa City," where the Osaka Prefecture College of Technology was located, and "Gakki" (instrument).

Broom Guitar

Broom GuitarAfter graduating from the advanced course at the technical college, you moved on to the Graduate School of Design at Kyushu University to research auditory illusion phenomena. Why did you choose this path?

Kubo: I learned the technology and importance of making things while studying mechanical engineering at the technical college. On top of that, one of the triggers was the Great East Japan Earthquake that occurred while I was at the college, which made me strongly desire to create things that stand close to people. To do that, I realized I needed to properly study human "psychology" and "experience." I decided to pursue the research field of auditory psychology, combining psychology with my love for music.

What exactly were you researching, by the way?

Kubo: I was researching an illusion phenomenon called "gap transfer illusion" (kūgeki ten'i sakkaku). Simply explained, it's the phenomenon where a sound that is actually interrupted sounds like it isn't, or conversely, a sound that isn't interrupted sounds like it is. During those two years of research, I constantly read papers on the mechanisms of the human brain and body. In particular, the book "Vision" by the British neuroscientist David Marr greatly influenced how I learned the significance and methods of studying the human brain.

So you expanded your focus of study and research from robots to the human body.

Kubo: Researching illusion phenomena leads to elucidating the process of the human brain—how humans hear sound and how they process it. Until then, during my time at the technical college, I was on the side of creating robots and various programs. Analyzing the human body, where these programs are actually embedded, was fascinating. I truly felt how wonderfully made the human body is.

After earning your master's degree, you joined a major instrument manufacturer and moved to Hamamatsu. Did you continue your Neya Gakki activities even while working on instrument production professionally?

Kubo: Yes. Balancing work and Neya Gakki was challenging, but the experience and knowledge gained from my hobby, Neya Gakki, could be utilized in my job, and conversely, the knowledge gained from my job could be applied to my hobby. I believed that this synergy between work and hobby would allow me to grow even further, so I continued both.

Amidst this, could you share the reason you left the instrument manufacturer in 2025 and established "Collet Instruments"?

Kubo: I felt that the core of what I wanted to do was still rooted in "uniqueness." While working at a large instrument manufacturer allows you to be involved in the design and development of various instruments, it becomes difficult to express my own individuality by pursuing "uniqueness." I decided to go independent because I wanted to engage in the kind of manufacturing that I truly wanted to do, even more than before.

The central business of Collet Instruments focuses on product development leveraging the technology called "MIDI 2.0." What exactly is MIDI in the first place?

Kubo: MIDI is a common standard created in the 1980s to connect electronic instruments. While USB and Bluetooth are now widely used, making it easy to connect devices, the internet was not prevalent at all when MIDI was born. MIDI, born in such a context, is now used in various situations, including PC-based music production, karaoke sound sources, and even controlling lighting equipment.

However, it's a technology that hasn't changed for over 40 years. I learned about MIDI in technical college and used it often because the mechanism was simple enough for students. But even back then, seniors taught it to me as an "ancient technology," and I honestly thought, "Is it really okay that no new technology has been adopted yet?"

Compared to the conventional MIDI 1.0, what functionalities does MIDI 2.0 have?

Kubo: MIDI 2.0 has various added features, so explaining all of them is difficult, but there are two major differences compared to the conventional version.

The first is the vast expansion of the data expression range. In MIDI 1.0, data could only be expressed in 7 bits, or 128 steps (from 0 to 127). MIDI 2.0 increases this to 32 bits, evolving significantly to over 65,000 steps. This change vastly expands the expression of, for example, the strength with which a keyboard key is pressed (the loudness of the sound) from 128 steps to over 65,000. Furthermore, finer adjustments for timbre and playing techniques are possible, allowing for a wide range of sonic nuance expression.

I see. What is the second change?

Kubo: It's bidirectional communication. Conventional MIDI 1.0 could only send data one way, from a transmitter to a receiver, making it time-consuming to confirm information or set up the destination device. However, with MIDI 2.0, data can be exchanged bidirectionally, making it easier to acquire information about each other's devices and automatically switch and set up modes, such as a piano-specific mode or a drum-specific mode. This significantly improves convenience for the user.

So you were attracted to MIDI 2.0, which enables freer sound expression.

Kubo: Yes. When MIDI 2.0 was announced during my time at the instrument manufacturer, I felt, "A new MIDI standard finally suitable for the modern age has appeared." However, even though I was deeply involved with MIDI 2.0 at work for a while, the hurdles for its adoption are very high. People don't like change, so when new technology emerges, they often say it's easier to stick with the conventional standard. Even several years after MIDI 2.0 was born, I felt that the industry's progress toward its adoption was stalled. That's why I decided to take the lead, feature MIDI 2.0, and aim to spread it to more people, which is how I started Collet Instruments.

Microtonal keyboard under development. A sensor attached to the keys detects finger movement, enabling fine pitch changes for each key. The control technology for the sensors utilizes know-how learned from robot construction.

Microtonal keyboard under development. A sensor attached to the keys detects finger movement, enabling fine pitch changes for each key. The control technology for the sensors utilizes know-how learned from robot construction.In October 2025, you started selling the "MIDI2USB CONVERTER Development Board," a circuit board that converts data between MIDI 1.0 and MIDI 2.0. This is a useful product for inexpensive operation verification of MIDI 2.0 software with existing MIDI 1.0 devices. What other products do you plan to announce?

Kubo: At the end of November, we will announce an electronic keyboard instrument capable of playing microtones. Microtones are finer musical intervals that cannot be expressed within the standard do-re-mi-fa-sol-la-ti-do scale. For example, a microtone is a pitch divided into smaller intervals than a semitone, such as between C and C-sharp. This keyboard leverages MIDI 2.0's characteristic ability to express sound more finely than before.

So, it's an electronic instrument realized specifically thanks to MIDI 2.0. You mentioned your desire to popularize MIDI 2.0 earlier. How do you envision the environment surrounding music production and performance changing as this technology spreads?

Kubo: I think music will become easier and more accessible for people who know nothing about MIDI to create. Right now, various data like images and videos are shared using smartphones. Most people probably aren't conscious of what data formats are being sent and how they're being transmitted. Conventional MIDI required users to consider things like which data was being sent from where. Still, with the bidirectional communication enabled by MIDI 2.0, I imagine that sound and music will be easily shared, and the number of new music pieces and music creators will steadily increase.

So you're looking beyond the proliferation of MIDI 2.0, toward a world where MIDI itself is not consciously thought about. How do you plan to grow your MIDI 2.0 related business going forward?

Kubo: First, I want to steadily advance our overseas expansion. Different music has been cultivated in countries and regions around the world. For example, concerning the microtonal keyboard I just introduced, I plan to extend sales channels to regions like India and the Middle East, where microtones are often used in traditional and modern popular music. While device sales will initially be the main focus of the business, I'm also considering the possibility of a licensing-based business model (patent pending) in the future.

Also, I believe MIDI 2.0 could potentially be used for controlling drones and robots, and I'm developing various ideas toward that realization. My priority is to create products that people who are unfamiliar with instruments or music can enjoy, and I want to try various challenges.

We certainly feel the further potential of MIDI 2.0. Finally, could you share your thoughts on participating in the ICT Startup League?

Kubo: Since I just went independent and started my business, I'm in a situation where I don't know left from right, so I'm very grateful to connect with people who are tackling startups in various fields. I hope to deepen connections with people from a wide range of industries going forward.

Music China 2025 exhibition. The MIDI2USB CONVERTER development board was displayed at the instrument trade show held in Shanghai, China, in October 2025.

Music China 2025 exhibition. The MIDI2USB CONVERTER development board was displayed at the instrument trade show held in Shanghai, China, in October 2025.Editor's Postscript

Though he didn't have the chance to learn instruments like the piano or violin as a child, he is now in the position of making instruments after going through various experiences—reflecting on his past, Mr. Kubo shared his desire: "I want people who are unfamiliar with instruments or music to know that the world of music is one of their options and opportunities."

The company name, "Collet," refers to a small component used to connect rotating tools. This interview deeply highlighted Mr. Kubo's love for both people and instruments, and his spirit of inquiry into manufacturing, as he spoke about wanting to be a bridge that connects various people with instruments.

■ICT Startup League

A support program launched in fiscal year 2023, triggered by the Ministry of Internal Affairs and Communications' "Startup Creation-Type Germination Research and Development Support Project."

The ICT Startup League supports startups through four pillars:

① R&D Funding / Hands-on Support

Up to 20 million yen in R&D funding is provided as a grant. In addition, regarding hands-on support, the selection and evaluation committee members who were involved in selecting league members will continue to stand by them after selection to promote their growth. A true "fandom-like" support system is built where evaluation committee members provide advice on business plans and growth opportunities to the companies they rated as "must-adopt."

② Discovery & Incubation

We provide opportunities for learning and networking to encourage the business growth of league members.

We also expand the base by developing activities to discover people aiming to start businesses in the future.

③ Competition & Co-creation

It serves as a field for positive competition like a sports league, where startups learn together and improve themselves while competing to win the necessary funds (up to 20 million yen). We also provide a place for co-creation where league members can collaborate to expand their businesses through various opportunities such as sessions with selection and evaluation committee members.

④ Dissemination

We will disseminate the initiatives of league members in collaboration with the media! By making businesses known to many people, we aim to expand new matching opportunities and chances.

■Related Websites

Collet Instruments

/

Collet Instruments (LEAGUE MEMBER)

/

ICT Startup League

InnoJin Integrates Telemedicine with Pharmacies: Resolving Fragmentation in Ophthalmology

iiba Signs Cooperation Agreement with Komaki City, Aichi to Develop Digital Childcare Map

For more details on STARTUP LEAGUE's startup support, please see here.