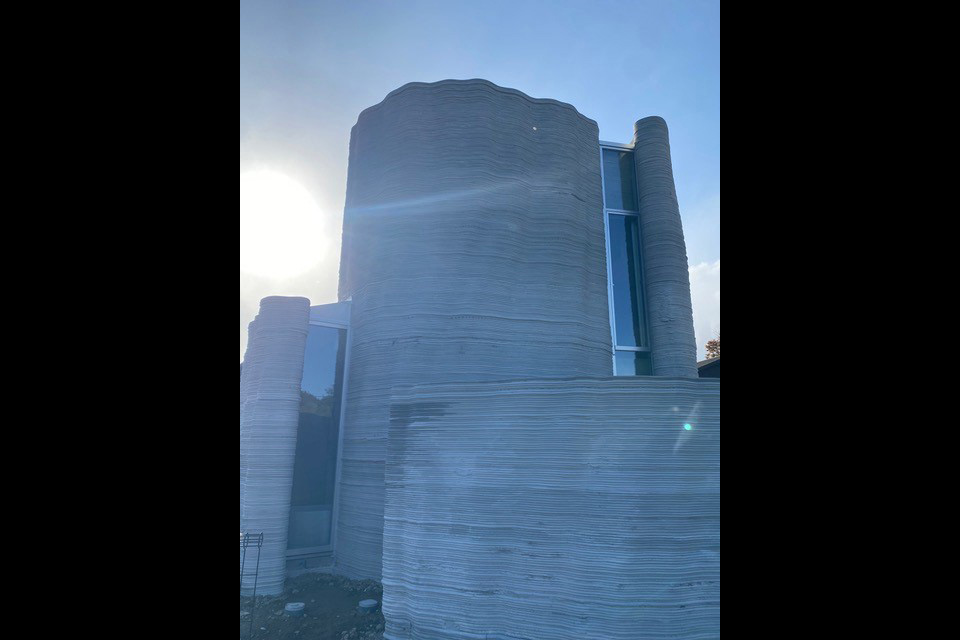

On November 7, 2025, KIZUKI Co., Ltd., a company promoting the social implementation of 3D concrete printing (3DCP) technology, announced the completion of Japan's first (*1) two-story 3D-printed house in Kurihara City, Miyagi Prefecture, in collaboration with ONOCOM Co., Ltd.

This was made possible by integrating diverse technologies from over 20 sponsoring and cooperating companies from Japan and abroad.

The most significant feature of this project is that it is the first time in Japan that 3DCP has been used to print the entire structure, from the foundation to the two-story framework, as a single piece on-site. Traditionally, the foundation, structure, and finishing have been separate processes handled by multiple contractors. In the construction of this house, however, most of the process was reportedly completed in one stop by a single 3D printer.

The material used is a specialized 3D printing mortar developed by SCG (Siam Cement Group), a major Thai building materials manufacturer. By adjusting it to meet Japan's building standards and climatic conditions and combining it with a large-scale 3D printer, the project achieved both precision and safety.

The interior features a kitchen (by Spacewasp) and other furnishings (by Sekisai) created with resin-based 3D printers, establishing a fusion of cutting-edge technology that integrates "technology x design."

Furthermore, the walls were simultaneously molded in a three-layer structure integrating architectural design, structural framing, and space for utilities. This "multifunctional wall" bulk construction drastically reduces on-site processes, increases freedom for plumbing and wiring, and minimizes construction errors and inconsistencies.

As many homes in Japan are two-story, it is believed that if a mass-production environment is established in the future, prices will decrease, bringing benefits to consumers.

This initiative, which consolidates advanced technologies (*2) into a single building, confirmed that it is possible to achieve cost reductions and high reproducibility while meeting residents' needs.

By establishing the process once, it will reportedly be possible to copy the same quality structure without a team of experts having to redo detailed designs each time, as is conventional.

KIZUKI Co., Ltd. plans to apply the knowledge gained from this housing construction to apply 3DCP technology to civil engineering structures, disaster prevention and defense infrastructure, and disaster recovery fields.

The company aims to establish a sustainable construction industry model by developing construction training programs and digital construction management systems.

With the technology to "print" construction at its core, the company intends to transmit the next generation of construction models from Japan to the world. In the Philippines, they will reportedly collaborate with ONOCOM to advance technological development.

LIXIL, Yamaguchi Sangyo, Showa Chemical Industry, Sekisui Plastics, Sika Japan, Fonte Trading, Sekisai, Spacewasp, Wintech, JFD Engineering, Kinan, NIKKEN CORPORATION, Se-FHA, Studio55, CUPIX, SCG etc. and 20 other companies

*1: The first two-story 3D-printed house in Japan to have obtained building confirmation, passed completion inspection, and been sold. (According to KIZUKI research / Based on building confirmation application, completion inspection, and sales records; surveyed November 2025)

*2: Advanced technologies: Materials, design, construction methods, two types of insulation, resin-based 3D-printed interiors, polishing techniques, automated marking, etc.

■ICT Startup League

This support program was launched in FY2023, originating from the Ministry of Internal Affairs and Communications' "Support Program for Startup-Oriented Germination R&D."

The ICT Startup League supports startups through four pillars:

①R&D Funding / Hands-on Support

Up to 20 million yen in R&D expenses is provided in the form of subsidies. Additionally, through hands-on support, the selection committee members involved in choosing league members continue to mentor and promote their growth post-selection. For companies that a committee member "absolutely wants to select," a "push" support system is established where the committee member themselves provides ongoing support, such as advice on business plans and offering growth opportunities.

②Discovery & Development

We provide opportunities for learning and networking to promote the business growth of league members.

We also work to discover aspiring entrepreneurs, aiming to expand the base of talent.

③Competition & Co-creation

It serves as a place for positive competition, much like a sports league, with a system where startups learn together, compete constructively, and win the funding they truly need (up to 20 million yen). We also provide a co-creation space where league members can collaborate and expand their businesses through various opportunities, such as sessions with selection committee members.

④Promotion

We collaborate with the media to publicize the initiatives of our league members! By making their businesses known to many, we aim to expand opportunities for new matching and chances.

■Related Websites

ICT Startup League

/

KIZUKI Co., Ltd. (Official Site)

/

KIZUKI Co., Ltd. (LEAGUE MEMBER)

InnoJin Integrates Telemedicine with Pharmacies: Resolving Fragmentation in Ophthalmology

iiba Signs Cooperation Agreement with Komaki City, Aichi to Develop Digital Childcare Map

For more details on STARTUP LEAGUE's startup support, please see here.