The "2040 Problem" looming over the future of Japanese manufacturing—severe labor shortages caused by a shrinking population and delayed automation in sectors like food, cosmetics, and pharmaceuticals—has become a critical management issue that can no longer wait.

To overcome this crisis, Closer Inc. is a startup triggering a revolution through its unique "robot platform."

The CEO, Shota Higuchi, is a young entrepreneur who achieved the prestigious feat of winning the world championship at "RoboCup," the pinnacle of robotics competition. Why hasn't industrial robot adoption spread across many manufacturing sectors until now? We dive deep into Closer's robot development, which addresses this problem head-on.

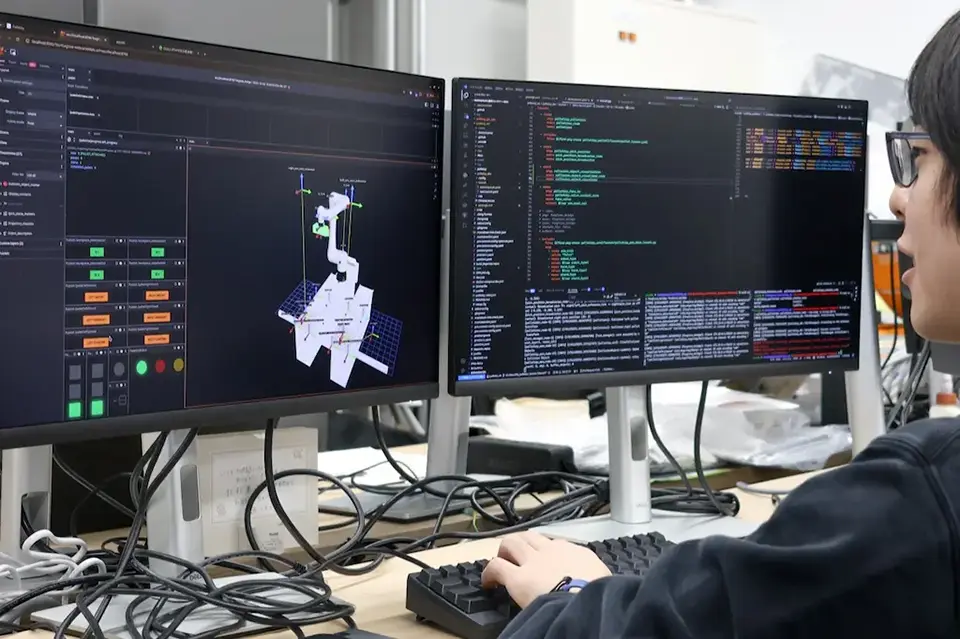

Robot development scene

Robot development scene

First, could you please give us a brief profile of yourself, Mr. Higuchi?

Higuchi: I am Shota Higuchi, CEO of Closer Inc., and I am currently 28 years old. I have been consistently involved in robot development since I was a child. In particular, I participated in "RoboCup," a soccer robot competition, since elementary school, and during my time at a technical college (Kosen), my dream came true when I won the world championship. Through these activities, I systematically learned the technologies necessary for robotics, including mechanics, circuit design, embedded systems, and programming.

Currently, at Closer, we leverage the technologies cultivated through robot development to provide "robot packages" that enable easy automation, specifically for factories in the food, cosmetics, and pharmaceutical industries. This business aims to use the power of software to solve serious labor shortages and cost issues on-site that conventional robot technology could not address.

You've been interested in robotics since you were young, but what originally sparked your love for building robots?

Higuchi: I was a child who loved crafts and making things. From there, I got hooked on electronic crafts using motors, like Tamiya construction kits, and gradually entered the world of microcomputer-controlled autonomous robots. I was deeply fascinated by the mechanism where the robot itself judges the situation and thinks for its movements, rather than being operated by a human like a radio-controlled car.

That enthusiasm eventually led you to the global stage of "RoboCup."

Higuchi: RoboCup was more than just a competition; it was the ultimate practical learning environment for me. The most important aspect of this activity was the need to develop and integrate all the elemental technologies required to move a robot by ourselves. Specifically, this included mechanical design, embedded control systems, and programming to give the robot intelligence. I was able to learn all of this systematically through practice. This directly connects to the development of the robot platform we are currently building at Closer.

Robot control systems

Robot control systems

We heard that your experience researching automatic tomato harvesting robots during your technical college days was a major turning point for your current business. What specifically was that turning point?

Higuchi: Through my research activities, I frequently interviewed farmers and food factories. What I witnessed there was the reality of severe labor shortages, the burden of heavy labor, and the fact that existing robot technology was not helping at all. Until then, I had been honing my skills to realize the "robots I wanted to build" through challenges like RoboCup, but from that point on, I began to want to create robots that the world truly needs.

To realize that vision, you decided to start your company while still in graduate school at the University of Tsukuba.

Higuchi: When I entered the University of Tsukuba, where robot development is flourishing, I initially thought the barrier to robot adoption was the price of hardware, so I focused on creating low-cost robot arms. However, as I observed the field through various activities, I realized that the highest cost in implementing industrial robots was the software adjustment tailored to the site—specifically, "System Integration (SI) costs." Therefore, I decided to shift my focus to software development.

Japan has excellent industrial robot hardware (such as arms) that we can be proud of globally. I conducted research on how to combine this superior hardware with our unique software to reduce SI costs—the main bottleneck—and established Closer Inc. in November 2021, when we generated our first sales from a robot we built.

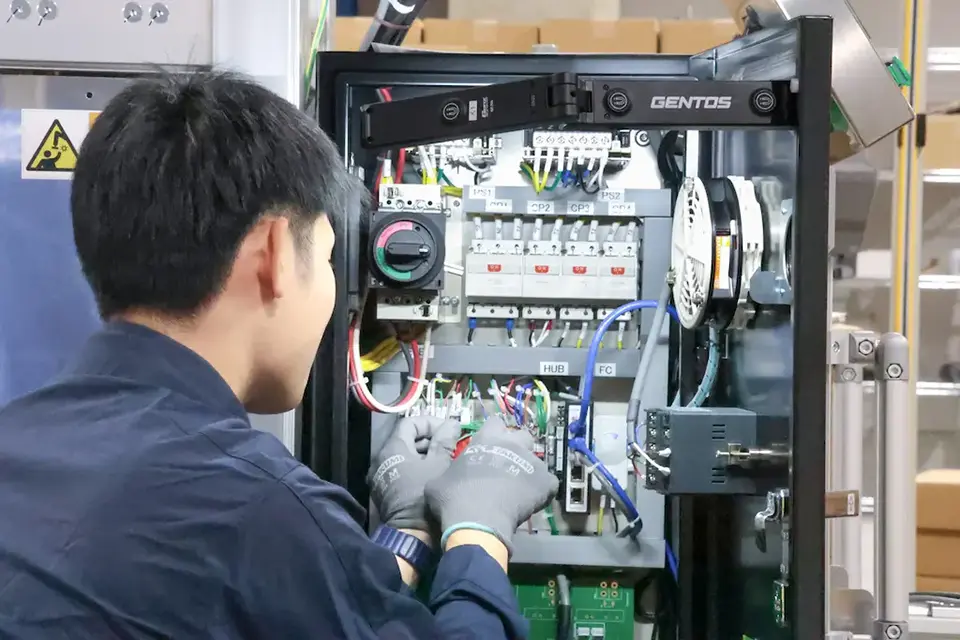

Manufacturing and testing site

Manufacturing and testing site

Could you describe Closer's current business activities?

Higuchi: We provide "robot packages" that are compact, low-cost, and require no specialized knowledge for high-mix, low-volume production lines in the food, cosmetics, and pharmaceutical industries (the "three-product industries"). While mass production lines for major manufacturers' flagship products are automated, other lines still rely heavily on manual labor and face serious labor shortages. We develop robots to solve challenges specific to these industries, such as the variability in food shapes and the limited physical space available for robot installation, which differs from the relatively automated automotive or electronics industries.

Why has automation been so slow to progress in Japanese manufacturing, particularly in the three-product industries Closer serves?

Higuchi: This is deeply related to the history of progress in industrial robots and Factory Automation (FA) in Japan, and the challenges are particularly evident in the three-product industries we focus on.

The first issue is that many industrial robots currently in operation are built and operated using very old mechanisms (Programmable Logic Controllers: PLCs). Conventional Japanese industrial robots based on PLCs were developed in the automotive and electronics industries, characterized by a simple and stable structure. They were highly valued in environments where it was necessary to handle mass-produced items with fixed shapes in fixed locations. However, the situation is different in food and cosmetics manufacturing, where high-mix, low-volume production is mainstream, and a single line handles containers and bags of various shapes and sizes.

Secondly, many companies in the automotive and electronics sectors could realistically develop their own industrial robots and introduce them to production lines because they have many engineers in-house. In contrast, such talent is rare within the three-product industries. Because they couldn't implement conventional industrial robots that require specialized engineers to operate, automation has struggled to advance.

I see. How is Closer solving these challenges as you tackle production line automation head-on?

Higuchi: We are solving these issues with our core technology—a "proprietary robot software platform"—and the "teaching-less technology" it enables.

First, to modernize legacy robot systems running on PLCs, we developed a proprietary robot software platform that runs on modern mainstream technologies like C++ and Python, much like a PC. This has realized a unique platform that can flexibly incorporate various technologies, including AI, creating a foundation for robot development that can handle high-mix, low-volume production lines.

Furthermore, we developed "teaching-less" technology based on this software platform. Conventional robots required engineers to input complex 3D numerical values (teaching), but with our robots, on-site operators only need to input the "cardboard size" or "desired placement" on a tablet. Since the system uses AI to automatically generate the optimal motion patterns, no specialized knowledge is required. This allows on-site workers to change settings in a few minutes even when high-mix products flow through, achieving flexible automation in the three-product industries.

Our best-selling product, "Palletizy®," leverages this strength to excel in "compact, space-saving, yet high-performance palletizing" across various sites.

This unique software platform development also addresses the "implementation cost issue" mentioned earlier. Previously, it was necessary to pay high fees to System Integrators (SI) for custom robot adjustments at each site. By designing software and hardware as an integrated package and selling robots that can handle multiple product types, we have significantly reduced these high SI costs.

Additionally, in food and cosmetics production, there are many irregular items that change shape easily—like small sauce packets—or items with a glossy finish that are hard to recognize. With conventional technology, it was extremely difficult to accurately recognize, securely grasp, and place these irregular workpieces, and it was impossible to flexibly integrate the latest technologies like AI image recognition later. However, our "PickPacker®" has achieved industry-leading speeds for picking irregular items in bulk.

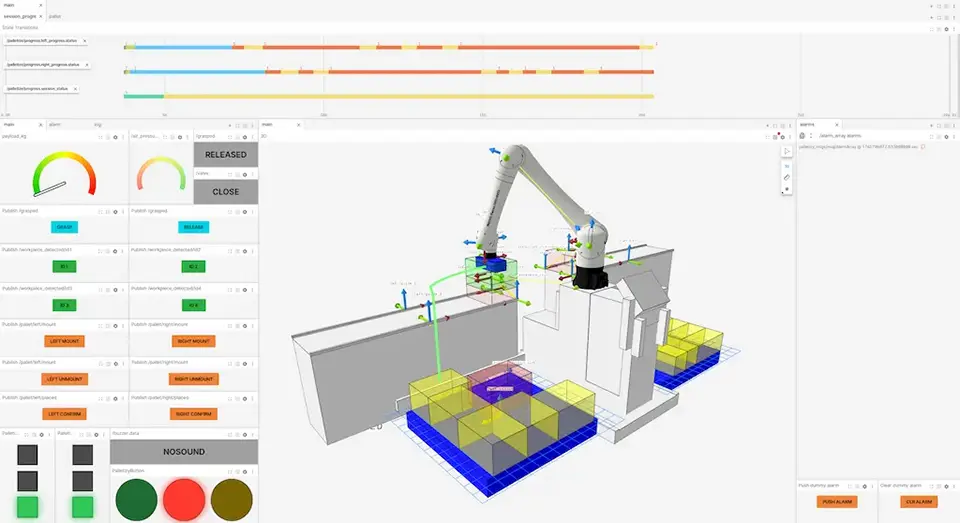

Palletizy® UI

Palletizy® UI

Could you tell us about your future business development, particularly regarding revenue?

Higuchi: Currently, sales have grown about four times compared to last year, and we aim to maintain an aggressive growth rate of about three times per year moving forward.

Regarding your scale-up plans, it seems you are focusing more on the quantitative expansion of current robots rather than opening new genres. Do you also have global expansion in mind?

Higuchi: Yes. First, we are pouring all our efforts into expanding our market share within our current target, the three-product industries, and establishing a mass production system for our robots. Since our system is highly versatile, we believe it can be applied to various tasks within this industry. Beyond that, based on our success in Japan and our mass production system, we plan to enter the global market as a solution to labor shortage problems. Furthermore, even in sectors like the automotive industry where developers are available, we will actively take on challenges where higher-level automation is required.

What is your outlook for the overall robot market in the future?

Higuchi: With the innovation in AI, the evolution of humanoid robots has been remarkable over the past year or so. However, in the actual environment of a factory, return on investment (ROI), speed, and stability are paramount. For the foreseeable future, industrial robots like arm-types, which specialize in specific tasks and are cost-effective, will continue to hold the advantage.

What role do you want Closer to play within that landscape?

Higuchi: We aim to be a leading Japanese company in the field of "Physical AI"—which, unlike "Generative AI" that functions in digital space, possesses a physical body like a robot and takes action while observing its surroundings. While many companies in this field are still at the stage of proof-of-concept or demonstrations, we want to actually implement this in society and become a company recognized by the world. Automating heavy labor and simple tasks creates an environment where workers can focus on "creative work that only humans can do." I feel this is the most essential way to regain the international competitiveness of Japanese manufacturing.

Working with a control panel

Working with a control panel

Finally, could you tell us your purpose for participating in the ICT Startup League and your current activities?

Higuchi: My goal for participating was to gain knowledge to scale ICT technology as a business, secure funding, and build a network with management experts and other entrepreneurs. The funding provided through the league has allowed development to proceed smoothly. As for the network, I plan to be active during the remaining period to acquire know-how and further expand our connections.

Editorial Note

Mr. Higuchi's passion for "autonomous robots" began with his childhood love for crafts, peaked with his experience as a RoboCup world champion, and has now evolved into Closer Inc.'s business philosophy of a "proprietary robot software platform."

What I felt strongly throughout the interview was his intense sense of mission and determination. He shifted from the investigative curiosity of a researcher to deciding to start a business with the conviction that "I must use my technology to solve social problems." This drive is the engine behind tackling difficult, high-mix, low-volume production sites like the three-product industries.

Conventional robot implementation was bound by the "chains of legacy systems," requiring high SI costs and advanced expertise. However, the new "robot software platform" developed by Closer has the potential to spread beyond the three-product industries to manufacturing lines throughout Japan and the world, becoming a new standard that replaces PLC-based industrial robots used for 50 years. If Japan's hardware strength crosses with Mr. Higuchi's world-class technical skills, this is certainly no pipe dream.

■ ICT Startup League

This is a support program launched in FY2023, sparked by the Ministry of Internal Affairs and Communications' "Project for Supporting Budding R&D for Startup Creation."

The ICT Startup League supports startups through four pillars:

① R&D Expenses / Hands-on Support

Up to 20 million yen in R&D expenses is provided in the form of subsidies. Furthermore, the selection committee members involved in choosing league members continue to support and promote growth after the selection. For companies that the evaluators "definitely want to adopt," a support system is built where the evaluators themselves provide ongoing advice on business plans and growth opportunities—truly a "fan-driven" support structure.

② Discovery & Cultivation

Providing opportunities for learning and networking that promote the business growth of league members. It also seeks to discover those aiming to start businesses in the future to expand the startup base.

③ Competition & Co-creation

Operating like a sports league, it is a place for positive competition where startups learn together and strive to win the necessary funds (up to 20 million yen). It also provides a space for co-creation where league members collaborate to expand their businesses through sessions with selection committee members and various other opportunities.

④ Dissemination

The league promotes the initiatives of its members in collaboration with the media. By making their businesses known to many, the program aims to expand opportunities for new matching and chances.

■ Related Websites

Closer, Inc.

/

Closer, Inc. (LEAGUE MEMBER)

/

ICT Startup League

InnoJin Integrates Telemedicine with Pharmacies: Resolving Fragmentation in Ophthalmology

iiba Signs Cooperation Agreement with Komaki City, Aichi to Develop Digital Childcare Map

For more details on STARTUP LEAGUE's startup support, please see here.